Harnessing the power of infrared technology, industrial ovens are a game-changer for several industries. These advanced heating systems, with their unique features and broad applications, are revolutionizing the way heat is tailored for industrial processes. From the core of infrared heat technology to the design of the ovens, everything about this equipment screams customization and efficiency. On another note, the advanced controls play a significant role in tailoring the heat solutions. These control systems not only improve energy efficiency, but also make high-temperature processes manageable. The rising market demand for these customizable industrial heating solutions speaks volumes about their growing significance.

Unleashing the Power of Customized Heat with Infrared Industrial Ovens

Embrace the innovative technology of infrared industrial ovens, a highly efficient and energy-saving solution for various industries. With the potential to revolutionize production processes, these ovens provide a unique blend of quality, efficiency, and customizability.

Examining the Core of Infrared Heat Technology for Industrial Ovens

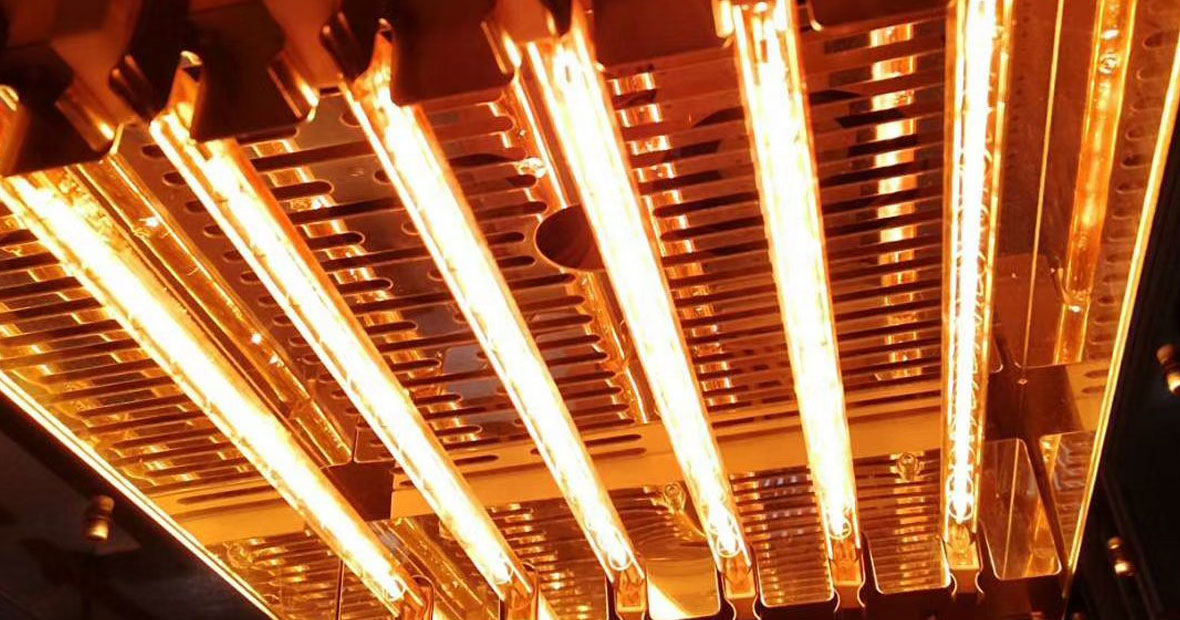

A deep dive into the technology behind infrared industrial ovens reveals a superior heating method. The ovens operate by emitting infrared radiation, which is absorbed directly by the product. This differs from traditional ovens, which heat the surrounding air. Thus, infrared technology delivers heat quickly and efficiently, reducing energy consumption and cost.

Infrared Oven Designs for Customized Heat Solutions

The design of infrared ovens is a testament to their efficiency. Each oven is tailored to meet specific industry needs, providing customized heat solutions. Unique features of these ovens include the ability to adjust the wavelength of the infrared radiation, allowing for precise control over the heating process. This customization impacts the quality of the final product, enhancing productivity and efficiency.

Quality and Efficiency in Infrared Industrial Oven Products

Infrared industrial ovens boast a higher performance compared to other oven types, due to their energy-saving nature and exceptional heat transfer capabilities. Their use contributes to sustainability and efficiency in industrial processes. Furthermore, these ovens are easy to use and maintain, with built-in safety measures.

Exploring the Unique Features of Infrared Heating Systems

Installation and operational costs of infrared heaters remain affordable, making them an appealing heating element for many. Furthermore, their environmental footprint is minimal, as they do not consume oxygen or emit harmful gases. Routine maintenance of this equipment ensures longevity and optimal performance. However, potential hazards or drawbacks warrant careful consideration and proper safety measures. Improving quality of life at home or the workplace, these systems find potential applications in various settings, including homes, offices, and public places. Recent or upcoming innovations in infrared heating technology continue to enhance its appeal and functionality. More on this site.

Delving into the Applications of Infrared Industrial Ovens in Various Industries

Infrared industrial ovens find extensive applications across diverse industries due to their unique heating capabilities. These ovens, equipped with advanced technology, optimize production processes, enhancing efficiency and productivity. For instance, automotive industries often employ these ovens for pre-heating or curing, resulting in improved product quality and reduced production time. In addition to their efficiency, infrared industrial ovens adhere to stringent safety standards. To illustrate, the National Fire Protection Association (NFPA) and Underwriters Laboratories (UL) provide guidelines and standards for safe operation of these ovens, ensuring their safe use in industrial settings. Furthermore, infrared industrial ovens offer significant advantages over traditional heating methods. Unlike conventional ovens, they provide uniform heat distribution, reduced energy consumption, and faster heating times.

Spotlight on the Role of Advanced Controls in Tailoring Heat Solutions

Customized heat solutions are revolutionizing industries, with infrared industrial ovens playing a pivotal role. The heart of this transformation lies in the innovative application of advanced controls. By digging deeper into the concept of control in custom heat solutions, significant insights into the future of industrial heating are revealed.

Concept of Control in Custom Heat Solutions

Advanced controls present an innovative technique for tailoring heat solutions in various industrial processes. These cutting-edge mechanisms offer a platform for the creation of tailored heating solutions, thus enhancing efficiency and reducing operational costs. The control systems ensure consistent temperature, a factor that is fundamental in any industrial heating process.

Role of Advanced Controls in Improving Energy Efficiency

The role of advanced controls in energy efficiency is evident in the way they help trim down energy consumption. By allowing precise control of heat generation and distribution, advanced controls optimize energy usage, leading to substantial cost savings in the long run. For industries, this translates to improved bottom-line performance, making it a desirable innovation.

Advanced Control Systems for High Temperature Industrial Processes

High temperature industrial processes present unique challenges that can be effectively addressed through the application of advanced controls. These systems have the ability to adapt and respond to changes in the process environment, ensuring that the output remains consistent despite fluctuations in input variables. The result is a robust and reliable heating solution that meets the needs of today's demanding industrial applications.

Assessing the Market Demand for Customizable Industrial Heating Solutions

Understanding the market demand for customizable industrial heating solutions requires a keen eye for detailed analysis. The complexity of the market structure necessitates an in-depth exploration of various aspects, ranging from the practical aspects of industrial heating solutions to the benefits and potential savings they offer. A comprehensive understanding of these factors is instrumental in making informed business decisions.

Customizable industrial heating solutions provide an unparalleled level of flexibility and efficiency. These products, designed to cater to the specific needs of customers, have the potential to revolutionize the heating industry. By tailoring solutions with infrared industrial ovens, businesses can achieve optimal heating efficiency, thereby significantly reducing energy consumption and operational costs.